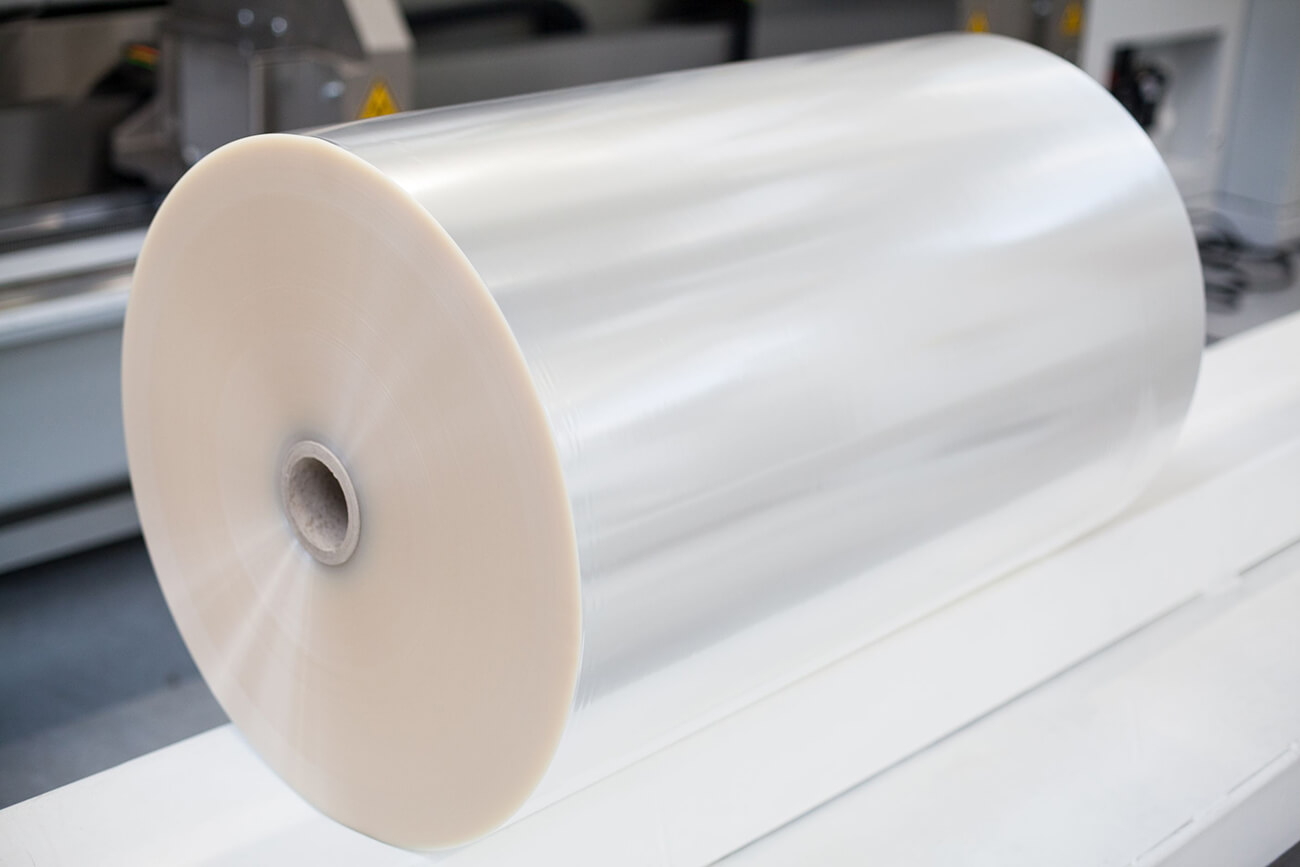

Production of VerCAST films takes place in conditions which guarantee the highest standards of cleanliness and hygiene. The process of CPP film production was certified for compliance with international standard of BRC/IOP.

VerCAST PP film ( CPP, non-oriented PP film) is a modern material of high transparency, perfect weldability and high mechanical resistance which is dedicated for producing a wide range of packaging, including food packaging – especially for bread (bread bags) and fresh vegetables (e.g. lettuce, carrots).

Our film is also used for the production of conical bags for packaging both flowers and fresh herbs in pots.

CPP is a great component of laminates with BOPP, PET, BOPET, PE films used for meat, cold cuts, and cheese packaging (trays covers).

Due to its mechanical properties and flexibility, comparable with LDPE film, CAST PP is ideal for perforation, which ensures ventilation for future packaging needed for example in case of clothes bags.

High transparency and gloss similar to BOPP film (oriented PP film) also foreordain CPP film for the production of high aesthetic quality products (e.g. magazine sleeves). The above mentioned features combined with great weldability make the film applicable in production of office supplies such as project files, binders, document sleeves, and school notebooks protectors.

VerCAST is a standard single-activated film prepared for being printed in flexographic printing and rotogravure, as well as for lamination.

Our lines for casting polypropylene film CAST PP are the most innovative installations of the kind in Europe. Thanks to those lines we are able to produce films of thickness ranging from 20 to 170 microns which consist of 3, 5, or 7 layers. Multilayer structure of VerCAST significantly influence the quality of the film improving its mechanical properties, increasing its mechanical durability and puncture resistance what is extremely important for the quality of final product.

Along with the specialists of a German company Reifenhäuser, which is the producer of our lines, we developed unique technology enabling us to attain, among others, the 7-layer foil of increased mechanical durability and puncture resistance.

Our goal is to guarantee products of the highest quality. Thus, we invested in modern solutions as far as storage is concerned. Our high bay warehouses can contain approximately 5000 Euro pallets, what allows us to have fast access to the products in the process of preparing the shipping for our Clients. Combination of internal and external logistic processes has made our Company a reliable and efficient supplier in terms of production, research, service, and continuity of delivery.

We are fast and effective, our delivery is realized in the possibly shortest period of time. Our own transportation make us flexible and available for Clients.

Quick responds to Clients needs and availability are our unquestionable virtues, and that is why our products have gained trust of both home and foreign Customers.

| Type | Description | Technical data |

|---|---|---|

| VerCAST BW | polypropylene CAST film dedicated for baked goods bags (bread bags); winter version |

Technical Data Sheet BW |

| VerCAST BS | polypropylene CAST film dedicated for baked goods bags (bread bags); summer version |

Technical Data Sheet BS |

| VerCAST L | polypropylene CAST film dedicated for lamination and flowers/herbs/other plants in pots |

Technical Data Sheet L |

| VerCAST La | polypropylene CAST film dedicated for lamination with lowered Sealing Initiation Temperature (SIT) |

Technical Data Sheet La |

| VerCAST Lw | white polypropylene CAST film ideal for lamination with BOPP, dedicated to production of packaging of hygiene products (wet wipes etc.) |

Technical Data Sheet Lw |

| VerCAST Lw(a) | white polypropylene CAST film dedicated for lamination with lowered Sealing Initiation Temperature (SIT), dedicated to production of packaging of hygiene products (wet wipes etc.) |

Technical Data Sheet Lw(a) |

| VerCAST F | polypropylene CAST film dedicated for freezing resistant packaging -25°C |

Technical Data Sheet F |

| VerCAST SF | low haze hybrid CAST film designed for the best performance in the packaging of frozen products |

Technical Data Sheet SF |

| VerCAST AF | polypropylene CAST film dedicated for lamination – packaging wet food such as fresh vegetables, fruit, cold cuts, meat |

Technical Data Sheet AF |

| VerCAST S | polypropylene CAST film dedicated for sterilization/pasteurization; food and medical packaging undergoing heat treatment |

Technical Data Sheet S |

| VerCAST OB | polypropylene CAST film dedicated for the production stationary articles i.e. documents’ sleeves |

Technical Data Sheet OB |

| VerCAST M | CAST film with micro perforation dedicated for producing both food and minor goods packaging; we can perforate any type of our CAST film; maximum width of the perforation: 1700 mm. |

no dedicated TDS |

Each manufacturing batch is scrutinized repeatedly in our laboratory. On the basis of organoleptic assessment as well as laboratory examination performed by our qualified personnel the film is released for sale. Consistency of recipes, production conditions, and modernity of our machine park make the properties of our film highly reproducible.

Each manufacturing batch is scrutinized repeatedly in our laboratory. On the basis of organoleptic assessment as well as laboratory examination performed by our qualified personnel the film is released for sale. Consistency of recipes, production conditions, and modernity of our machine park make the properties of our film highly reproducible.

All films are tested in terms of: